Your current position:Production Process

Production Process

Production Process:

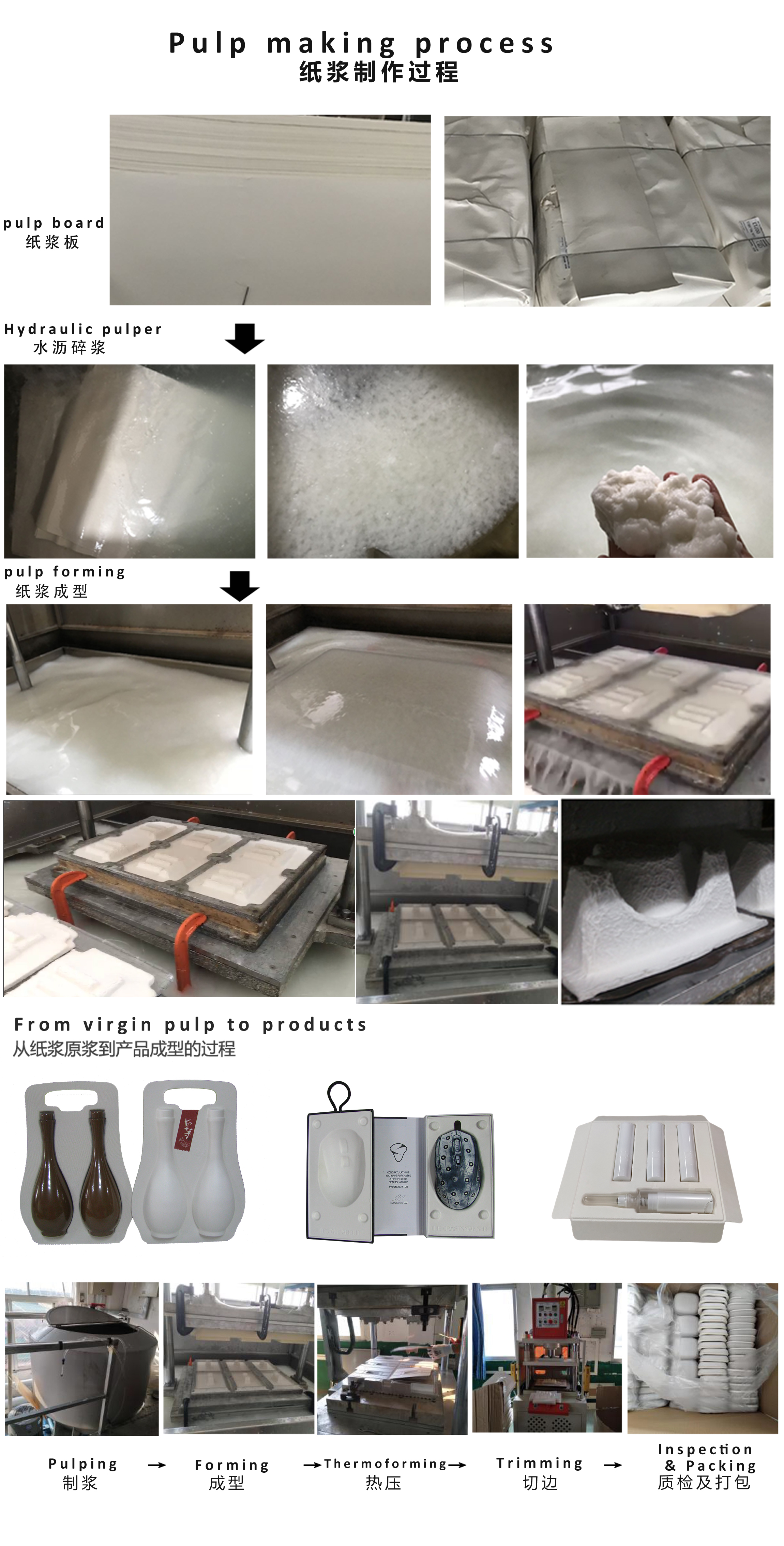

The production process of molded pulp products can be simply summarized as follow:

Pulp Preparing

The raw materials of molded pulp products are mainly some natural fiber like sugarcane bagasse, wheat straw, woodchip, bamboo, or recycled paper. Different materials can result in different physical properties (strength, thickness, color...)

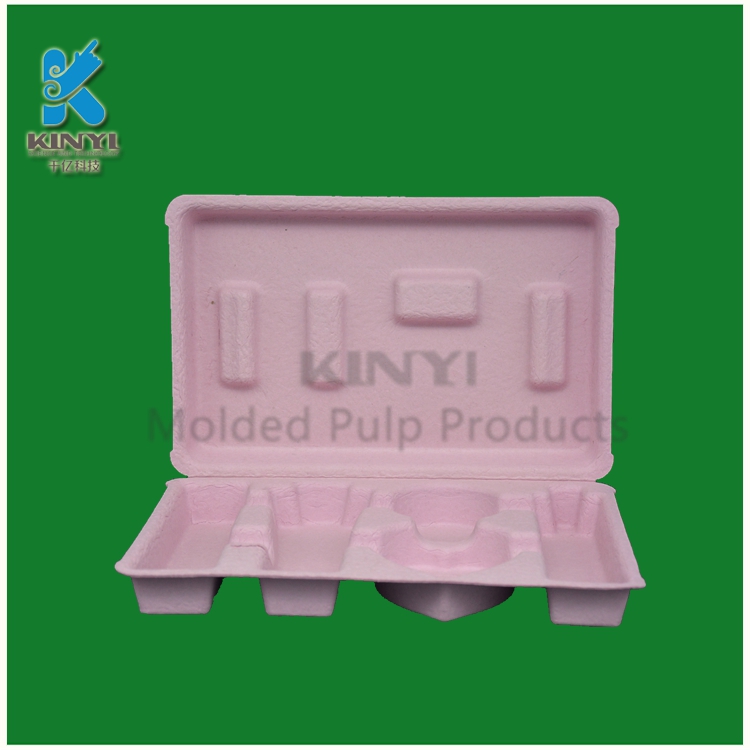

These raw materials are put into a giant blender with certain amount of water and turn into slurry. If needed, some additives are added in the slurry to make the products waterproof, flame-retardant, oil-resistant or stronger; or dyes can be mixed with the slurry to make products colorful.

Molding

The finished pulp then is conveyed to the forming machine where equipped with a mold in desired shape. The mold is with perforations in either or both sides to absorb the pulp to the mold by suction and/or vacuums. The products are formed in the desired shapes in this process.

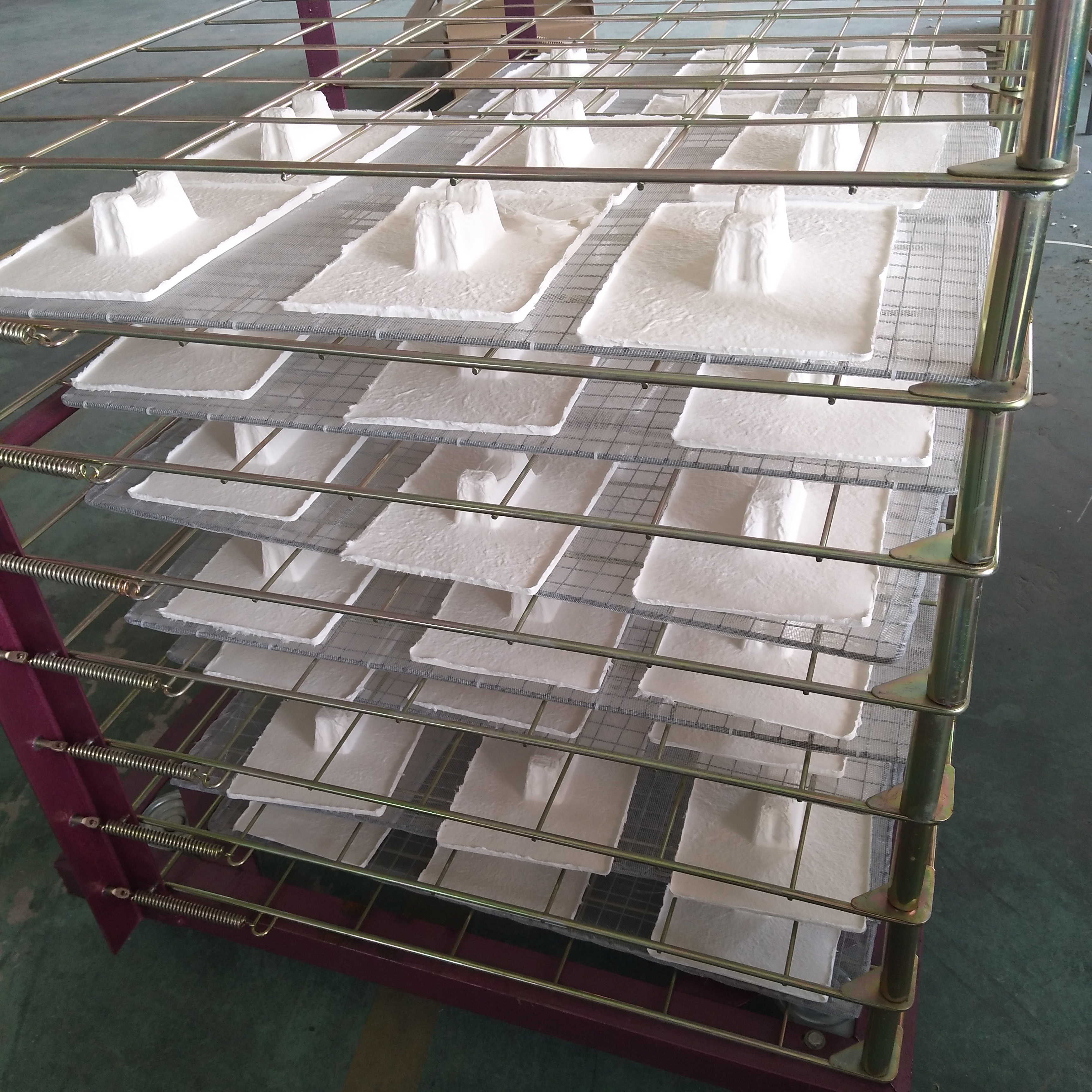

Drying

1). For the rough thick-walled type, the semi-finished products will go directly to the heater to eliminate the moisture;

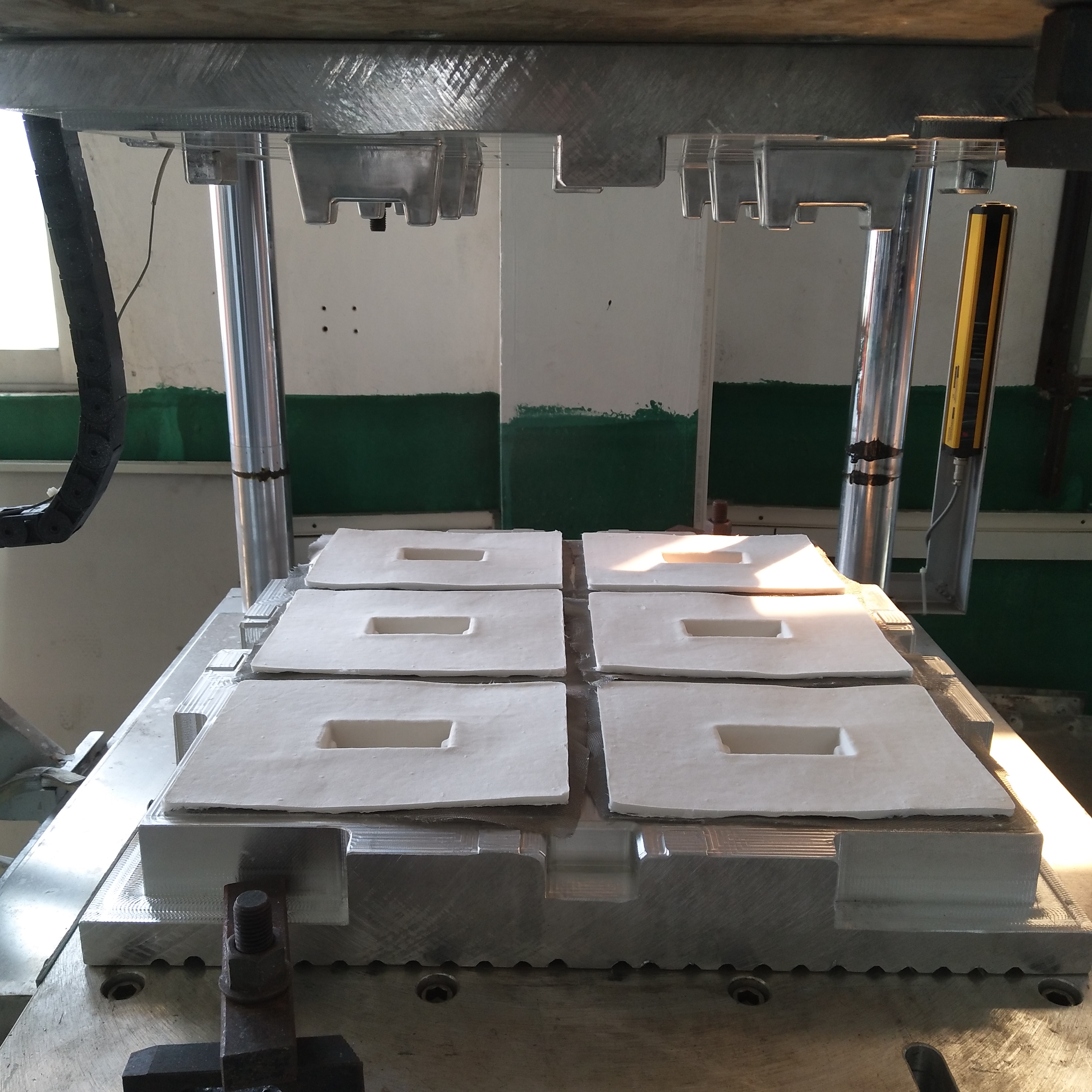

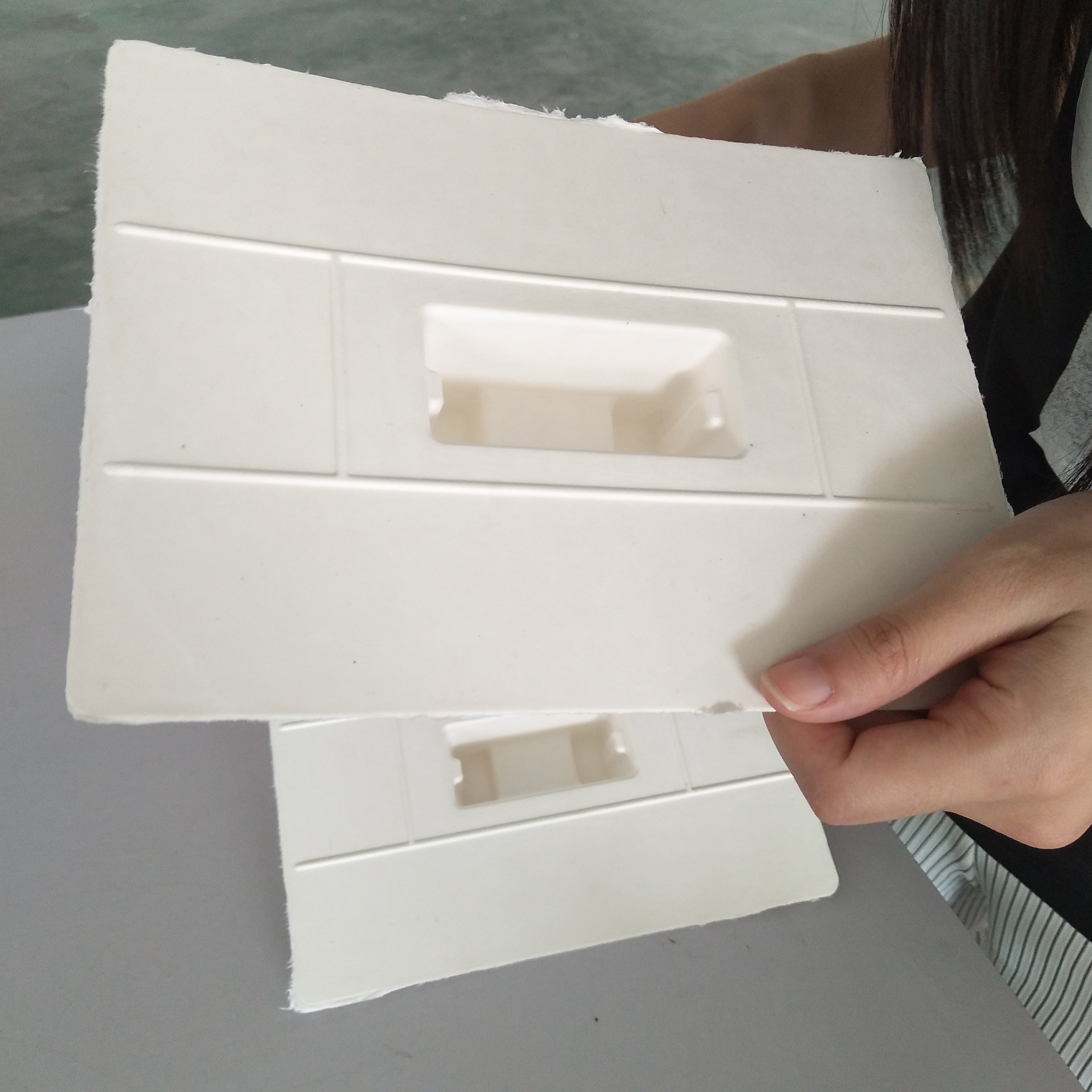

2). For the smoother thin-walled type, the semi-finished products first go to the heater to dry up, then they will need to go through the hot-pressing (transfer molding) process to achieve a smoother surface and form the final shape.

3). For the very smooth and refined type which look like the clear plastic, the semi-finished products will go to the thermoforming process in which the products are dried up in the mold and smoothened.

Cutting

The dried products can be cut based on the specific requirements in order to make the products more elegant and tidy. The products in need of punching and edge cutting entail more complicated manufacturing process and more precise edge-cutting die.

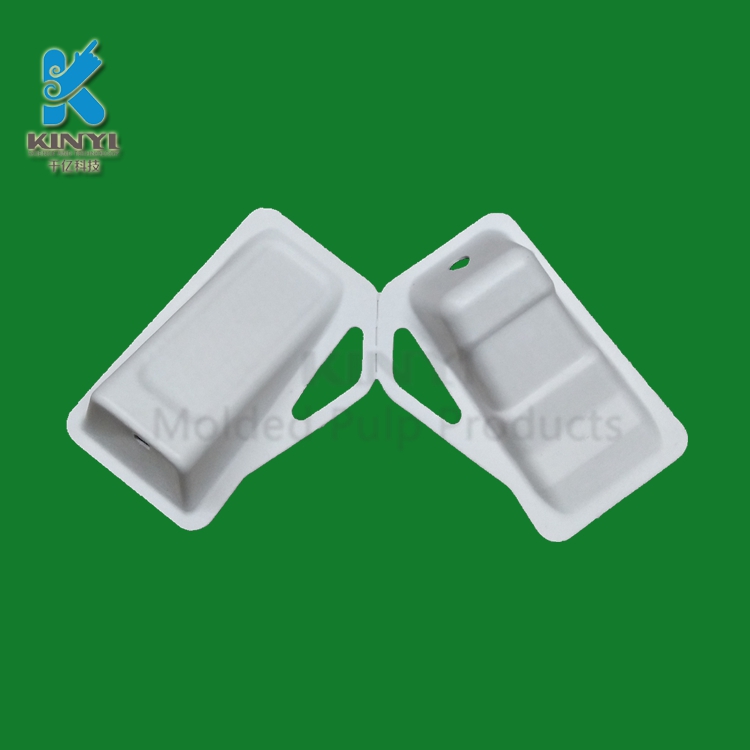

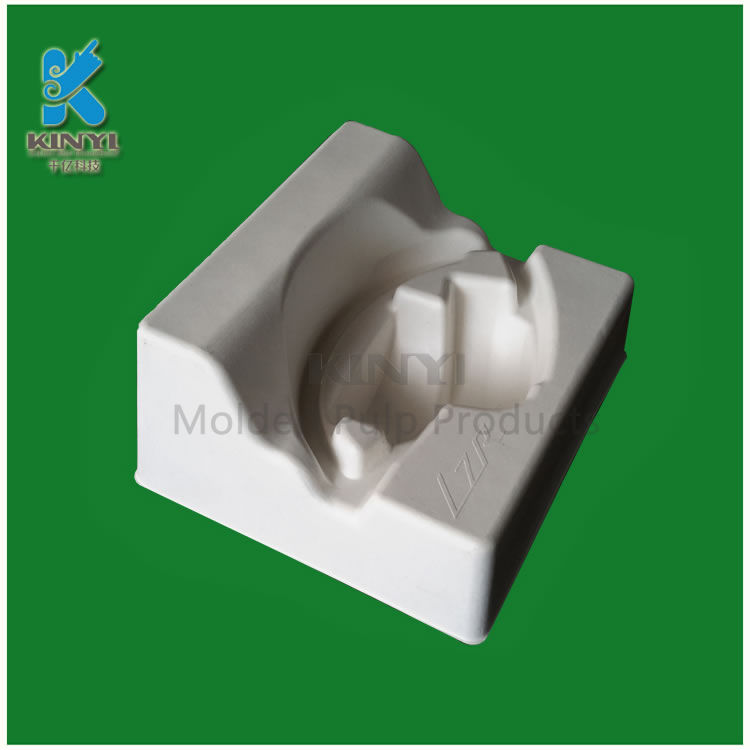

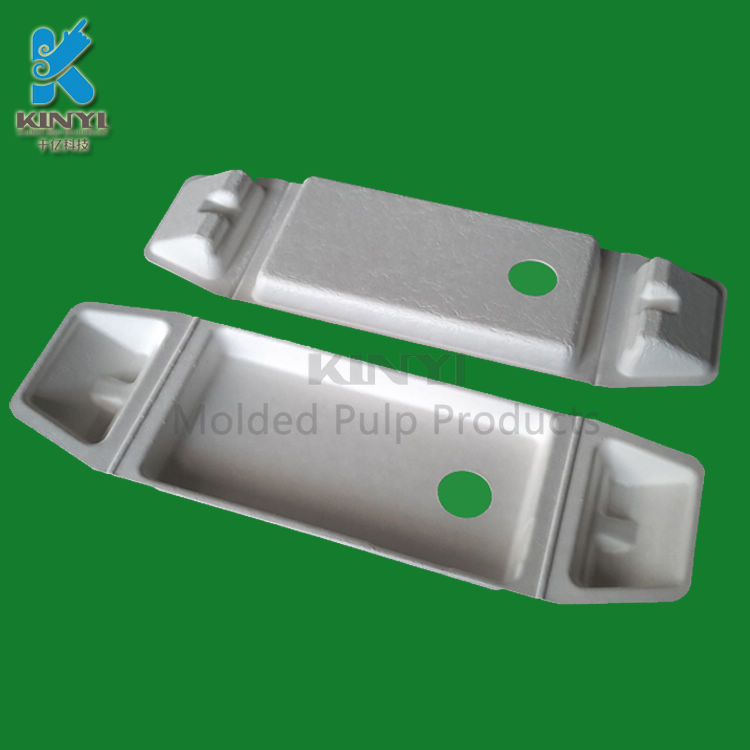

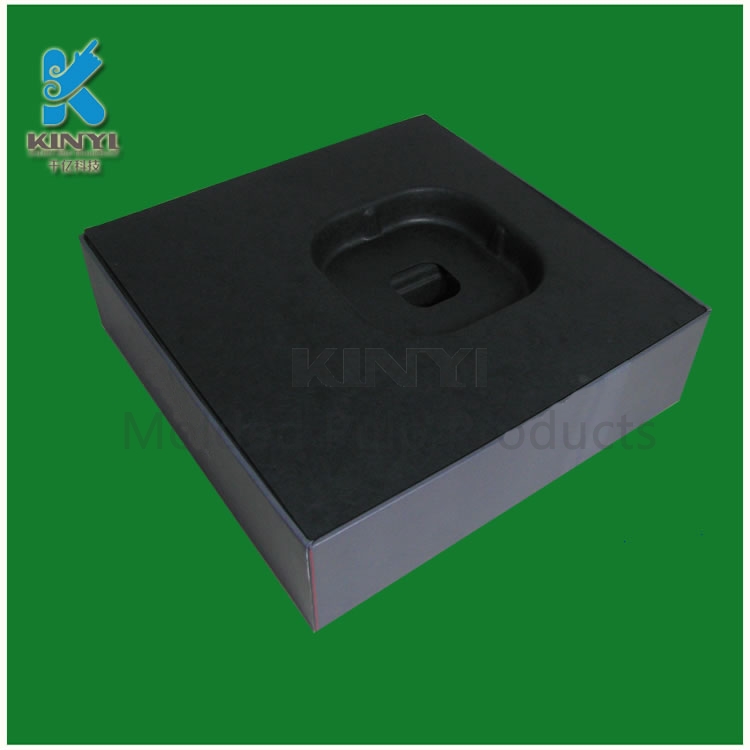

Different Types of Molded Pulp Products:

Supportive Services:

We specialized in design and manufacturing of molded pulp packaging, but we can also provide supportive services to save customers' trouble and time.

The supportive services we provide are:

1). 3D design drawings for molded pulp trays and turnkey packaging solutions;

2). Sourcing matching packaging like color boxes, paper tubes, cans, outer cartons, labels and etc;

3). Third-party factory audit, product inspection and sourcing of relevant products.

Forming

Thermoforming

Trimming

Inspection & Packing